In 2018, when we started to work on the concept, first escooter operators landed in Finland. We knew back then that the flimsiness of those scooters had already caused fatal accidents abroad. Their bad driving characteristic was caused by four distinctive design flaws that haven't been addressed properly - not even today, 5 years later.

Flaws of the 1st generation escooters

1. small tires

2. high center of gravity

3. weak brakes

4. bad frame geometry

2. high center of gravity

3. weak brakes

4. bad frame geometry

We wanted to address these issues, but we also wanted to add one secret ingredient to the concept, which was targeting the main cost-factor and the biggest source of co2-emissions of escooter fleet operators, namely the logistics behind re-locating and re-charging the scooters. Taking out the human factor out of the equation meant Viima had to be able to drive autonomously to re-charging points and to do the re-tours to departure locations or to other requested locations.

Self-balancing one or two-wheel vehicles, like the Segway, have tried to establish themselves on the market, but they have serious safety flaws for untrained drivers. Not really suitable for larger fleet operations. We wanted to have both: the proven concept of the electric scooter enhanced with self-balancing capabilities.

Viima self-balancing proof of concept

First geometry mockup

Shaping the initial form

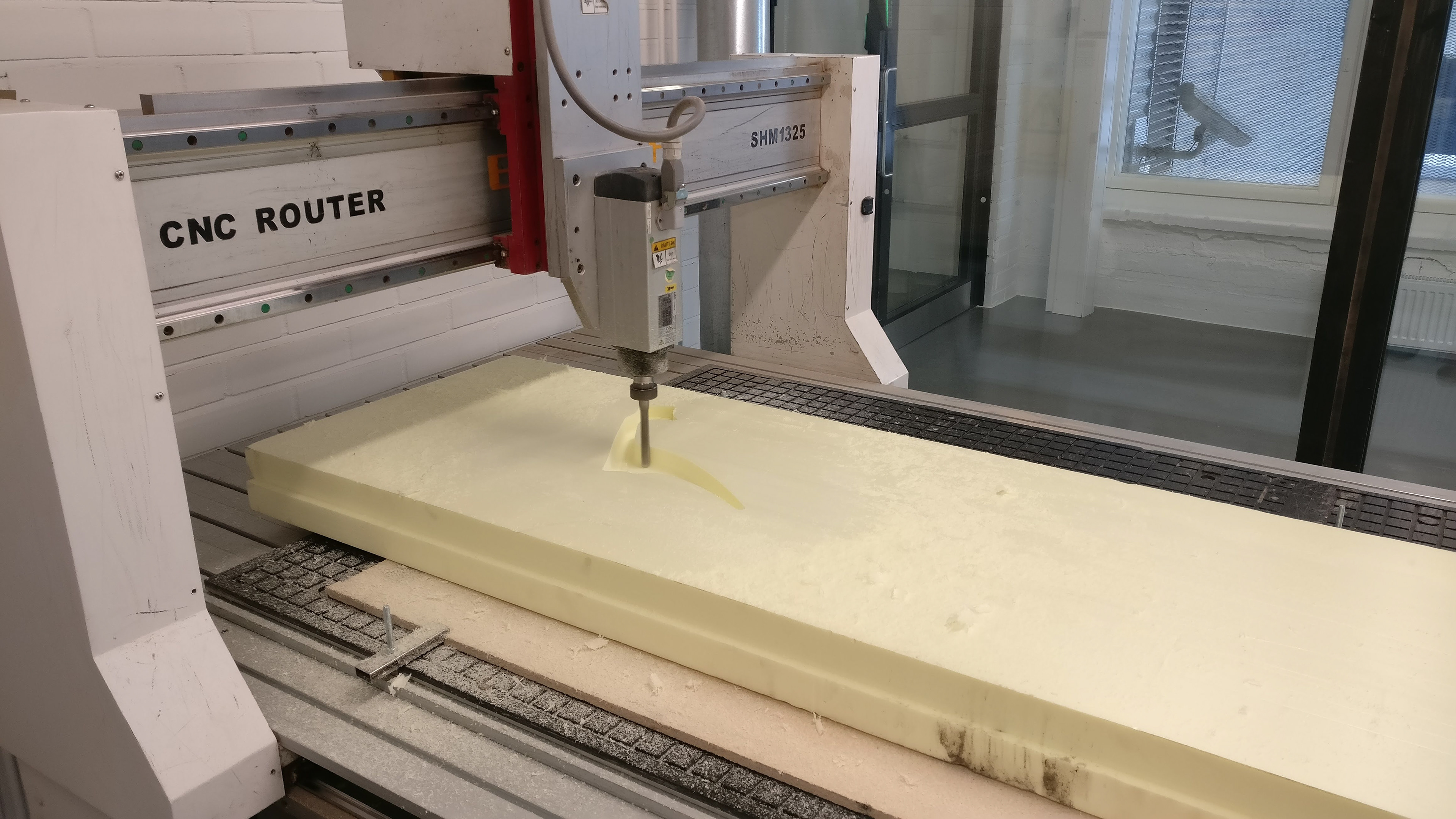

Foam routing the first 3D model

Bodywork model assembled

Bodywork mockup

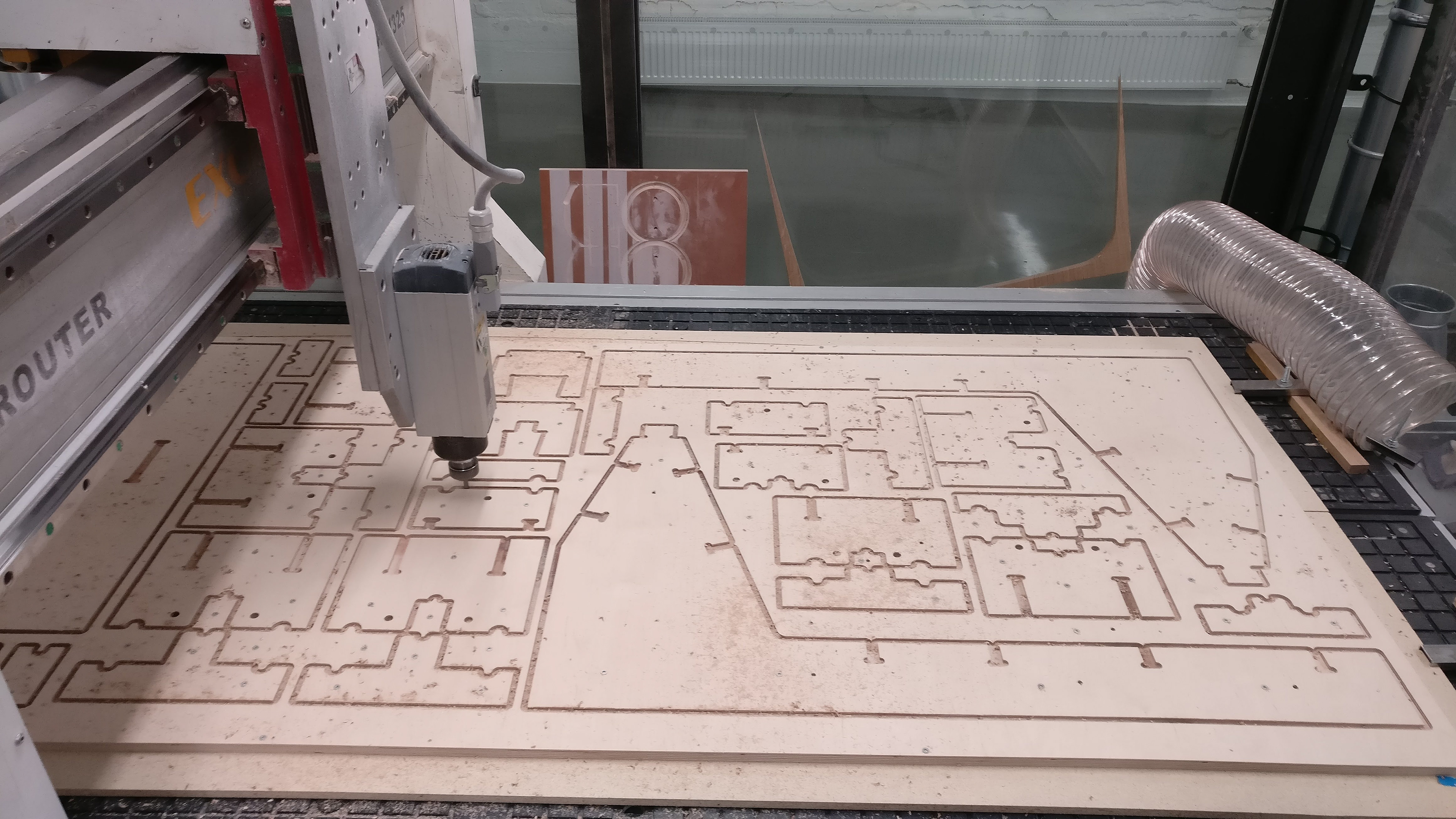

Routing the welding jig after design lock of the frame

Frame assembly in progress

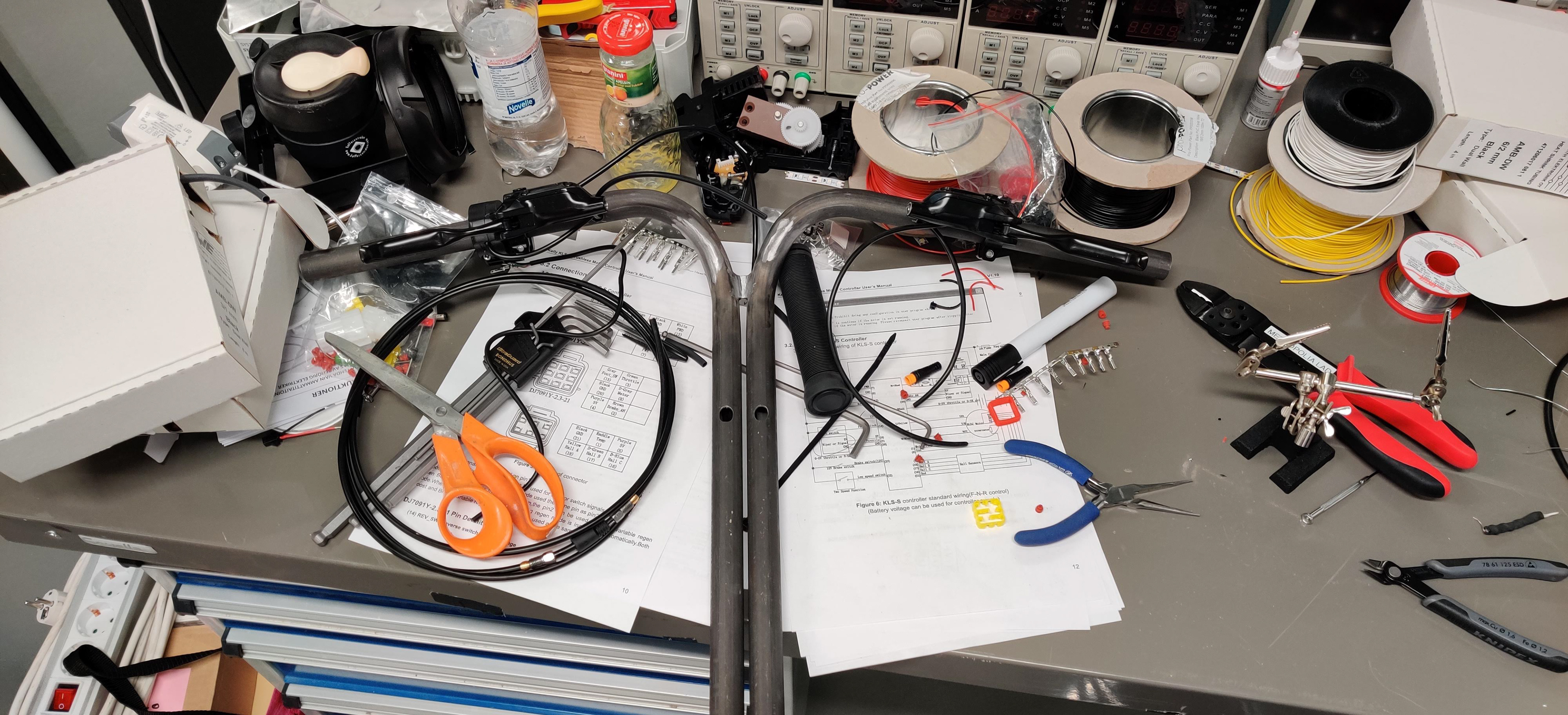

Wiring and electrical assembly

Functional prototype ready for a spin

The functional prototype (without balancing) was ready for a spin in spring 2019. At the same time the bodywork design was iterated to achieve a balanced appearance between the twin-tube frame and the shell to accommodate the battery and electronics.

A large 20" front tire was chosen as an unique design feature, but also as the main safety feature to prevent accidents caused by a smaller tire jamming in pot holes etc. The air-filled tire also cushioned the ride even without suspension.

The larger rim provided enough space for a powerful geared ebike hub-motor, which makes the ride truly an experience in itself by enabling rapid accelerations and steep hill climbs.

The third reason was to provide a reserved space for the self-balancing equipment in future.

Even though the body was rather a shell to cover the internals of the scooter, the plan was eventually to 3D print monocoque bodies with carbon fibre re-inforced thermoplastic. The monocoque would have had pockets to accommodate steel tubes for the front fork bearings and the rear fork tubes. Internal structure like the battery compartment and channels for cables would have been printed in place.

Assembly simplification and time savings would have been the obvious results. Furthermore the use of additive manufacturing would have opened the door for extensive customization based on customer requirements. In contrast to thermoset resins, commonly used in conjunction with carbon fiber, 3D printed plastic enables recycling at the end of its life-cycle.

Another aspect that has often been criticized in public escooters is the way people park them. Or in other words, how people toss them away after use. Due to mechanical shortcomings, especially escooters of the first generations lacked a proper kickstand to keep them upright during parking.

Often a small hit or a strong wind was enough to bring them to fall leaving the streets cluttered with obstacles. The main reason was a kickstand too short in regards to the scooter's total height.

Thus we opted for the widest possible kickstand we could accommodate in the frame. It doubles as the rear fender arms, which opens to both sides forming essentially a large tripod together with the front tire. This gives the frame a very good stability during parking.

The kickstand can also be motorized to have it extend by an electronic signal while driving autonomously. This is necessary for automated parking but also useful for longer stands to save energy for example in red lights etc.