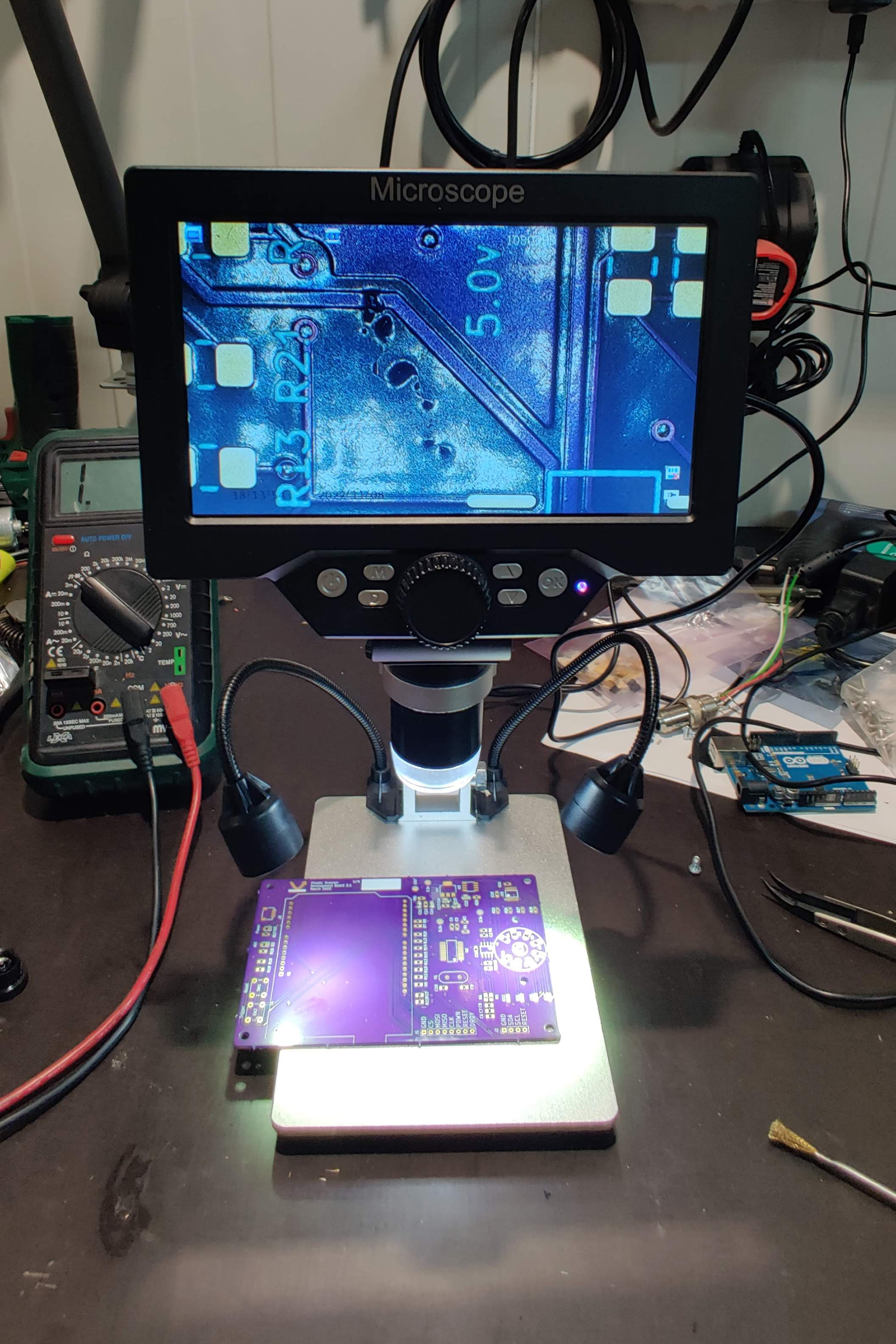

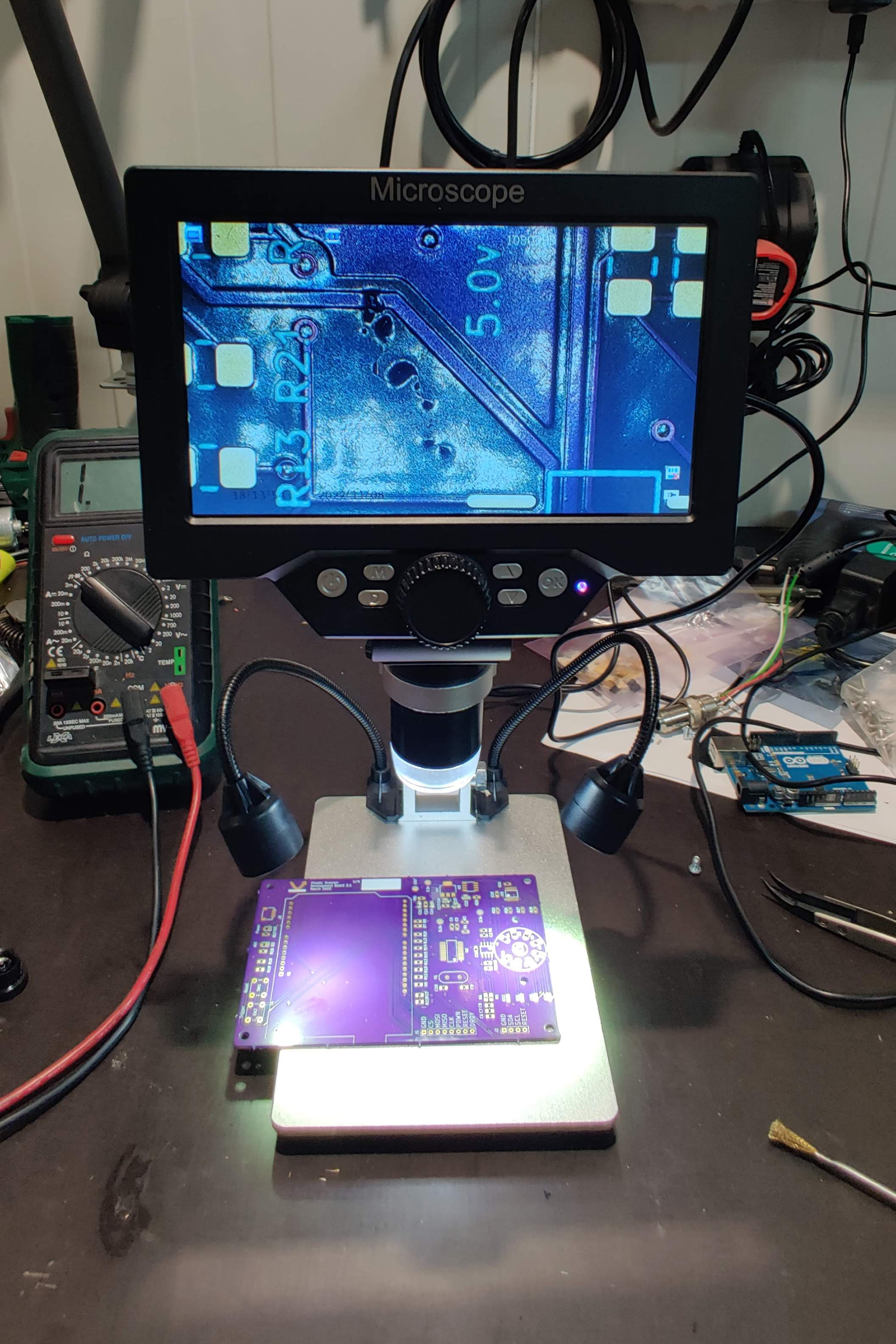

PCB under the microscope

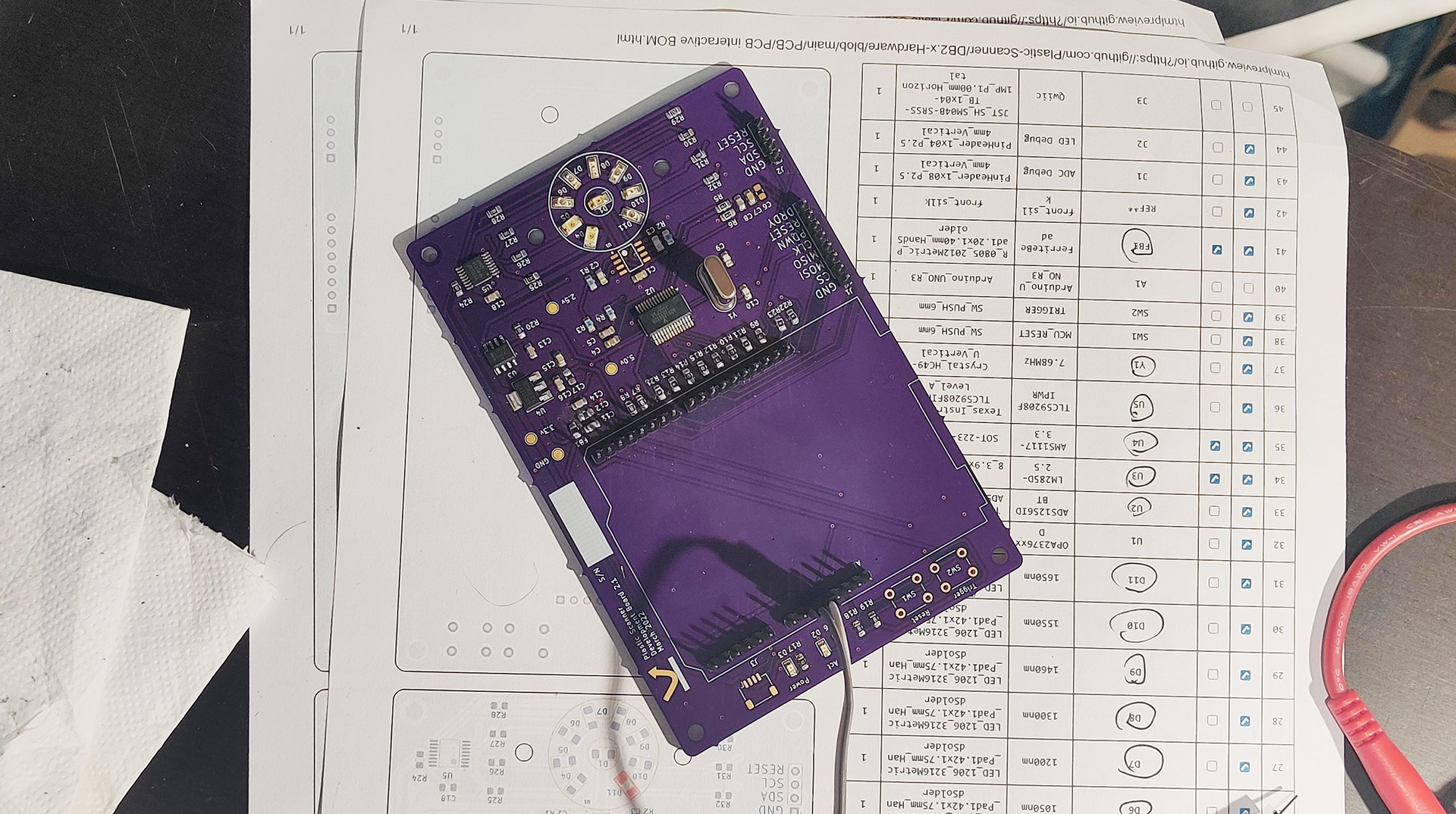

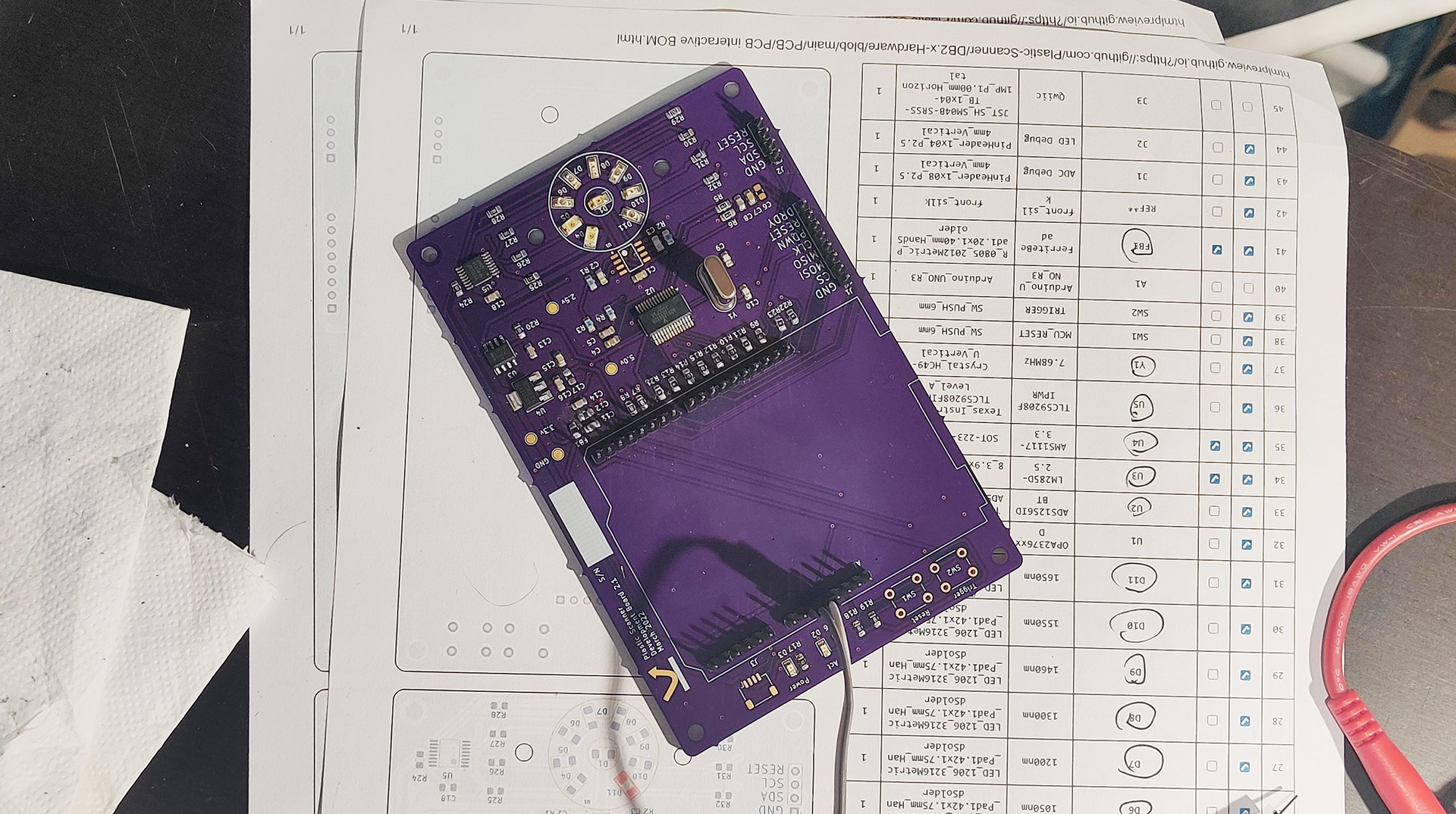

Testing circuit by circuit

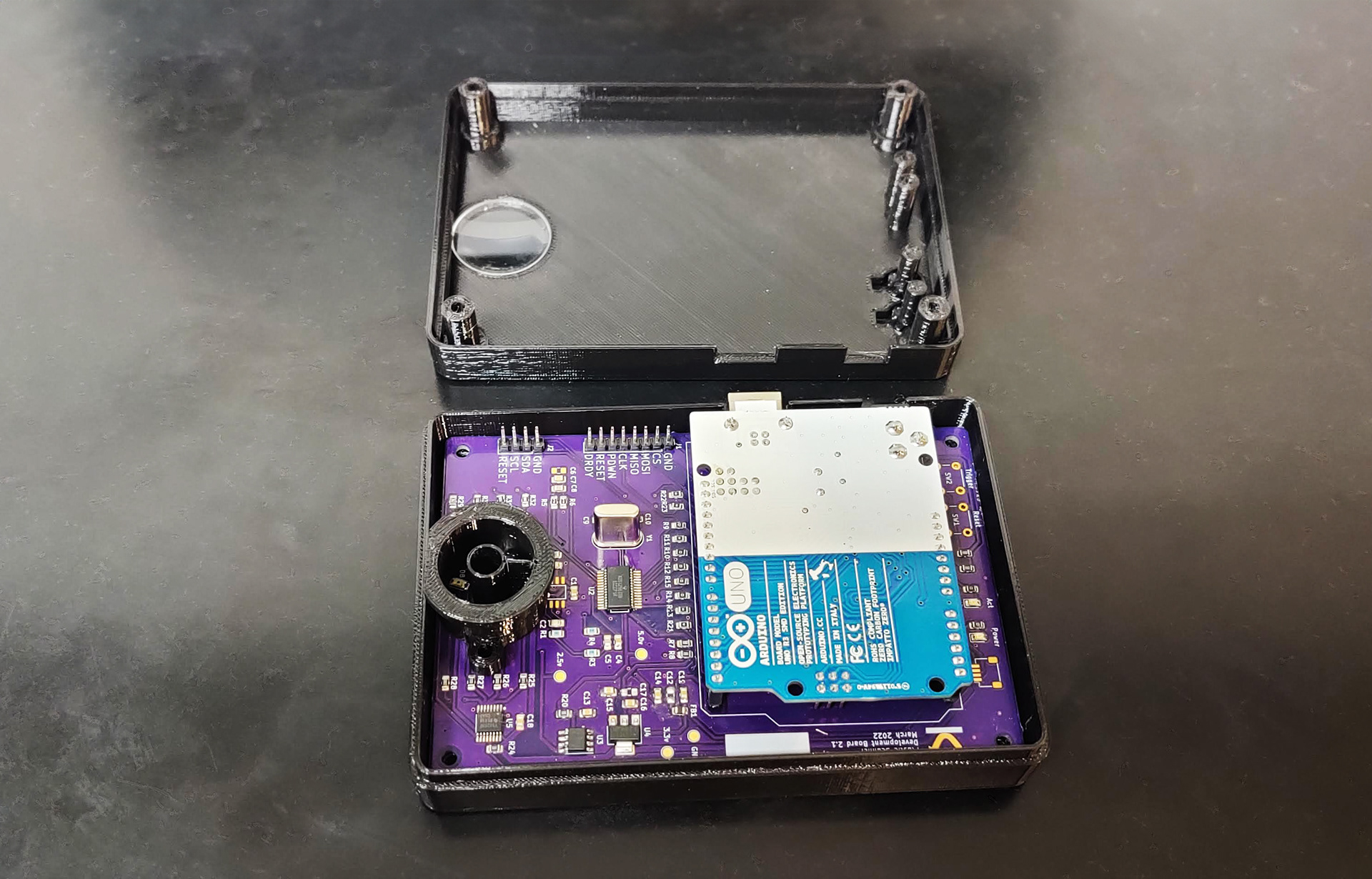

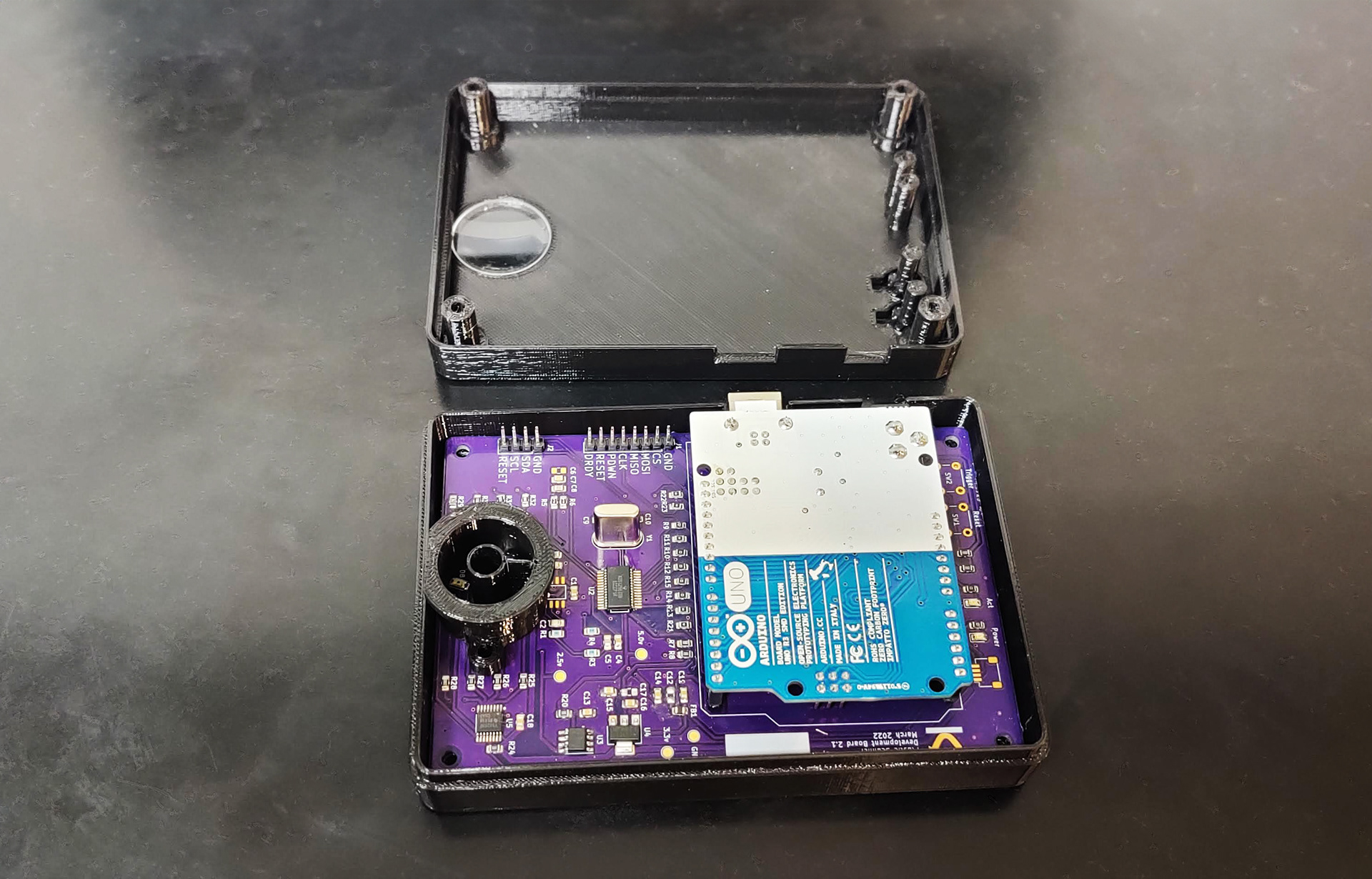

Finished assembly

Internals of the scanner

Assembled scanner

Plastic Scanner plotting software

Debugging sensor board

Scanning different plastic specimens

This build was an interesting project to test the current status of the near infrared spectrometer designed by the open source Plastic Scanner Project. The project aims to develop a low-cost alternative for plastic type identification. It is the single-most important step during plastic recycling to reliably identify the plastic type for effective sorting. For this purpose the recycling industry takes advantage of so called near infrared spectrometers which illuminates the plastic sample and measures the reflected light at multiple spots on the wavelength spectrum. Each plastic type can be identified based on an unique reflection pattern that spreads over the infrared spectrum.

Plastic Scanner plotting software

Debugging sensor board

Scanning different plastic specimens