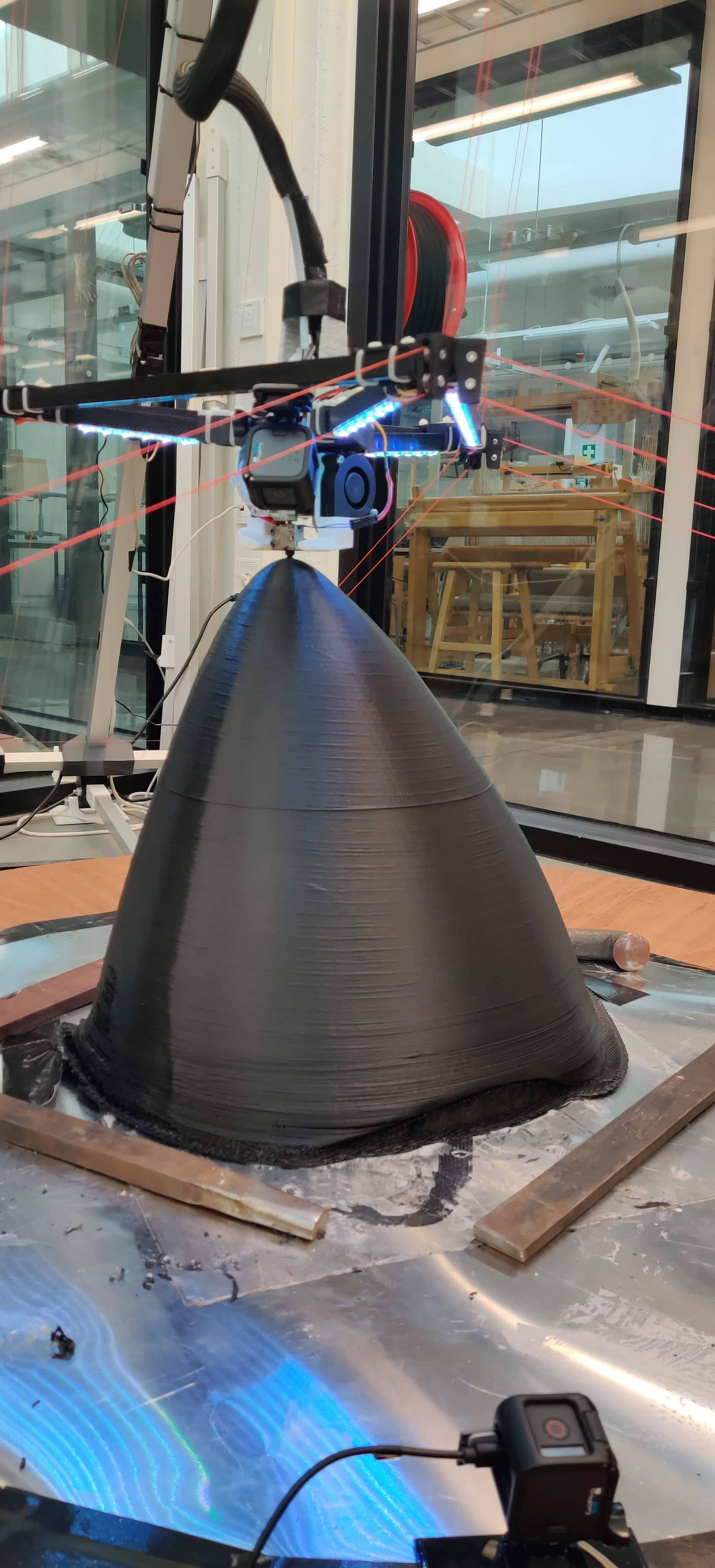

Minna wanted the shoe to look exactly like the original, so some consideration went into thinking how the shoe could be manufactured. First thoughts of making it out of real leather were dismissed, because the material would have behaved differently than in original scale. The inner shapes would have required complicated moldings, so we decided to 3D print the whole shoe, since we had our large scale 3D printer operational.

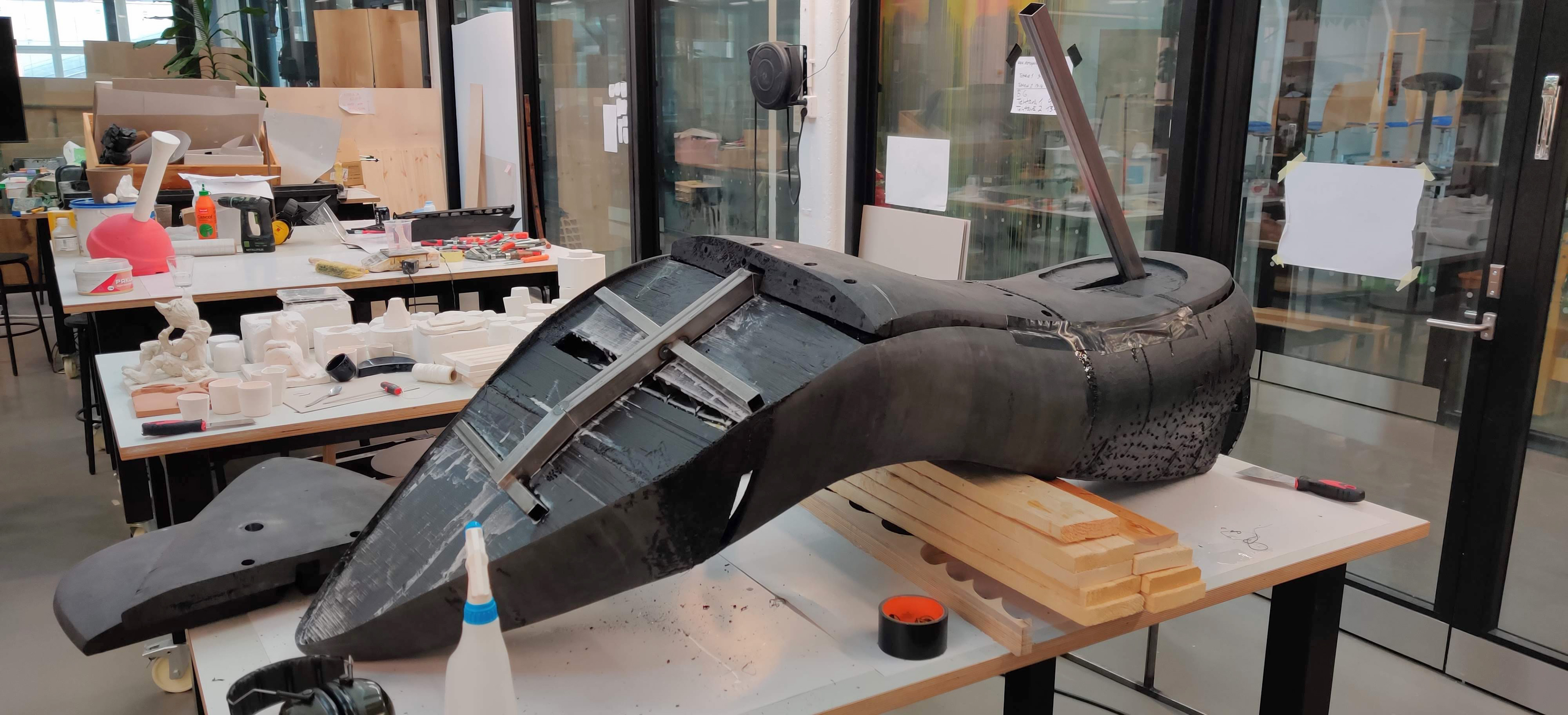

Although we could print big objects, the shoe had to be split up in 9 pieces due to its sheer size. The scale model is approx. 1 meter tall, 1.4 meter long and over half a meter wide. As it stands outdoor, exposed to the elements, it also needed to have a certain weight in order to prevent it from falling over in heavy wind. So, the weight summed up between 40-50 kg. We also reinforced the structural strength by adding a steel back bone between the sandwich-like parts of the shoe.

Fully biodegradable specialty filament was used to print the shoe. The material is biodegradable according to ISO 14855, it is food safe and it is 100% made from renewable resources. Compared to PLA it also has a much better temperature resistance. A feature that was important, since the shoe resides outdoors and is exposed to direct sunlight. The surface of the shoe was sealed by base coating and a high gloss finish to mimic a real patent leather appearance.

The shoe is displayed at the Minna Parikka flagship store in Helsinki.

3D-scanning the original shoe

First test print of the shoe model

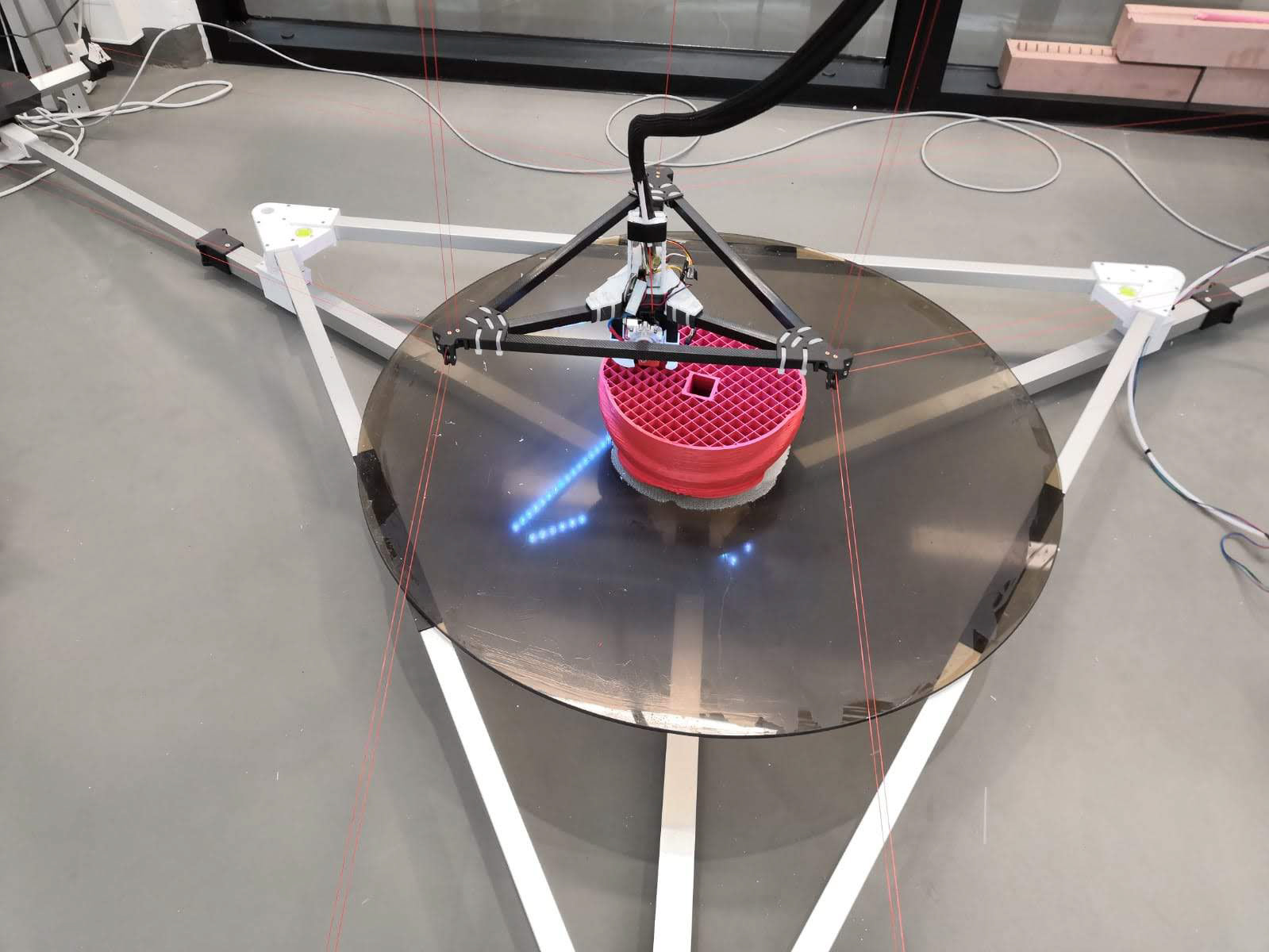

Printing the red ball

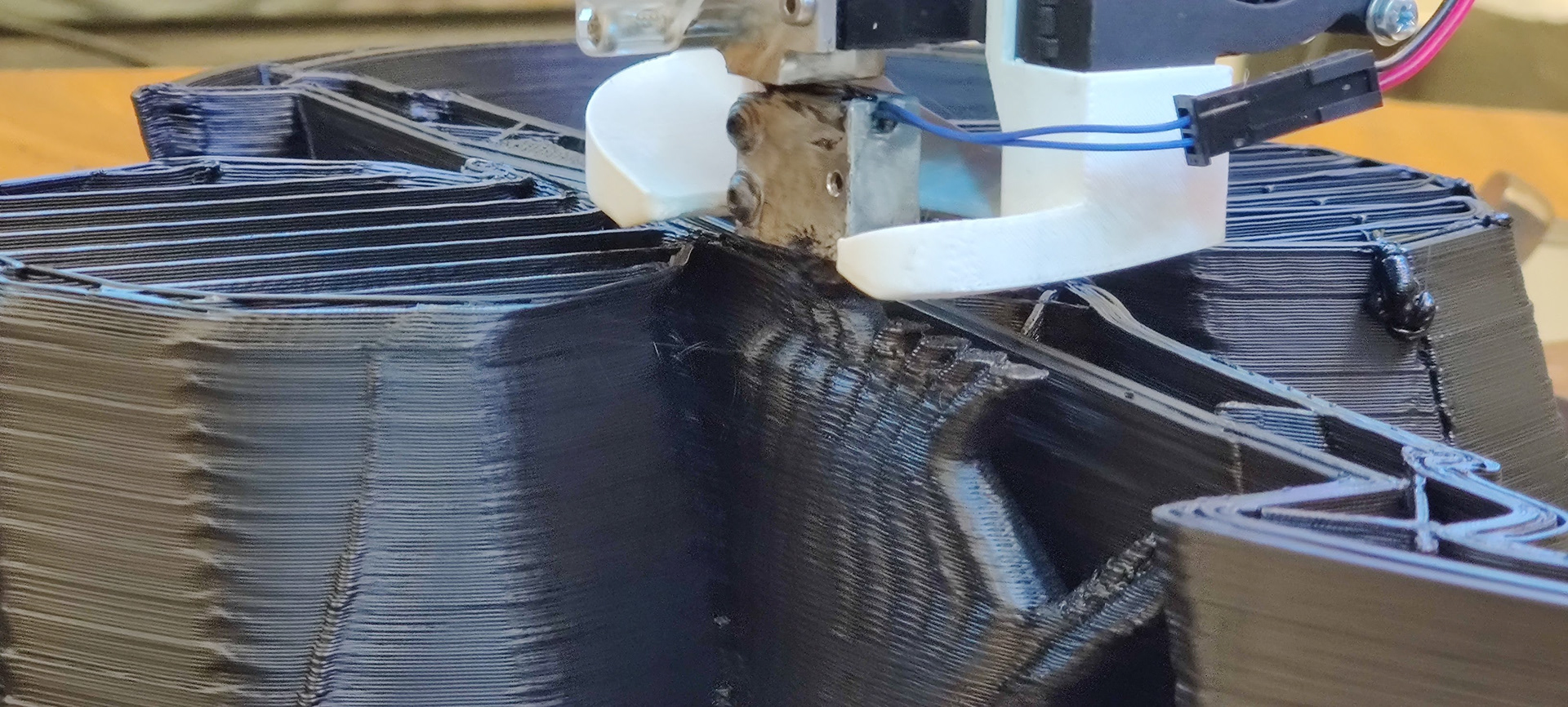

The tip of the shoe

Steel back bone

Assembly ongoing

Assembly ongoing

Shoe ready for surface finishing

First part of the paint job done

Can you see the small detail?

Top coat finished